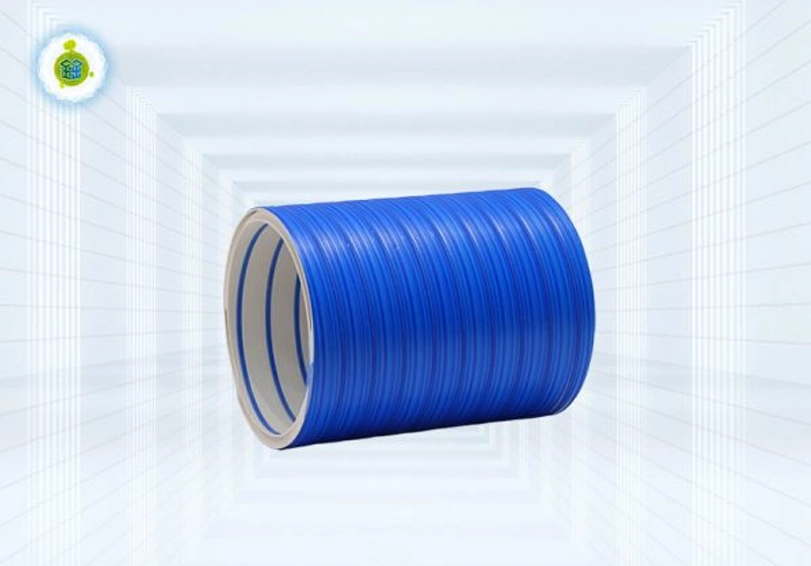

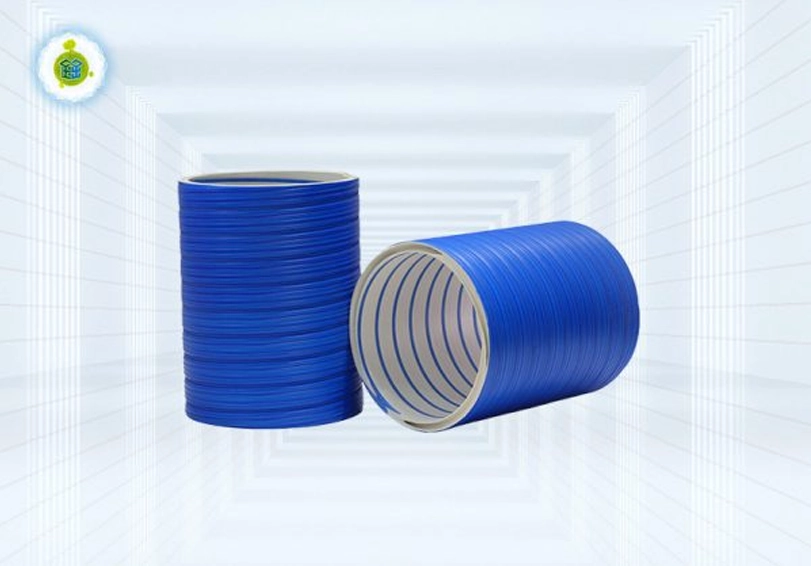

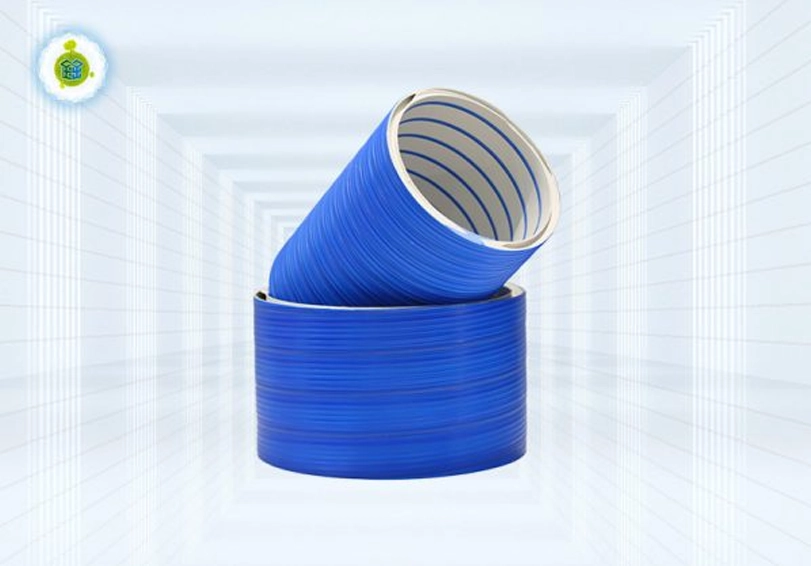

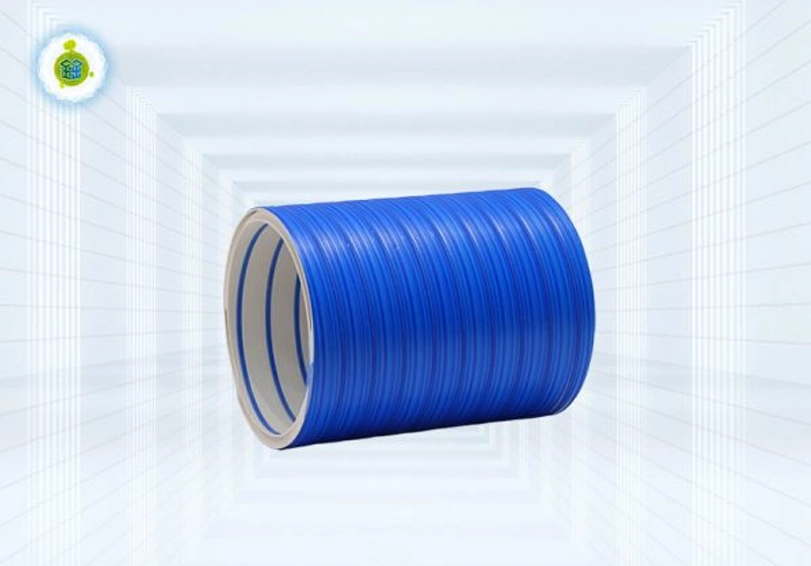

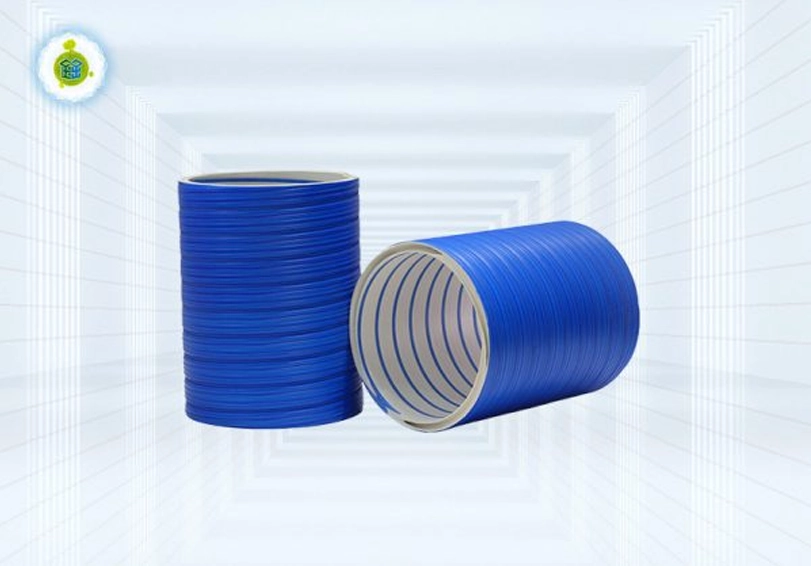

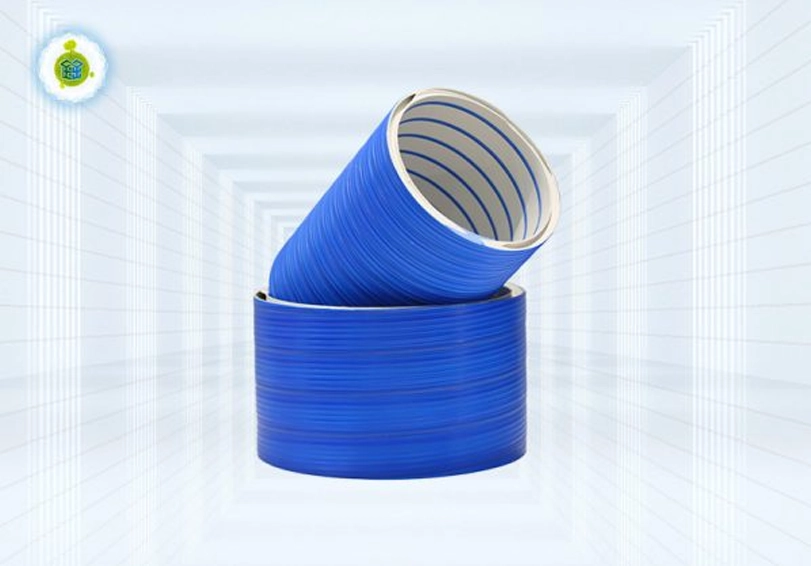

PP Spiral Wound Pipe Manufacturer

PP spiral wound pipe is made of polypropylene (PP) as the main raw material, which adopts a one-step molding process to extrude a specific trapezoid shape of the inner tube through the automatic extrusion equipment, and then composite structural wall pipe by winding technology through the molding machine.